MIL-DTL-17060G(SH)

3.5.2.1.10 Cable connectors. Connectors shall be of the solderless type in accordance with MIL-T-16366 (see

3.5.2.1.11 Temporary air filters. When specified (see 6.2), motors shall operate when air intakes are covered

by a filtering media (see 6.2) temporarily attached to the motor housing.

3.5.2.1.12 Dynamic balance. Unless otherwise specified (see 6.2), the degree of balance shall be precision

balance as specified in table V.

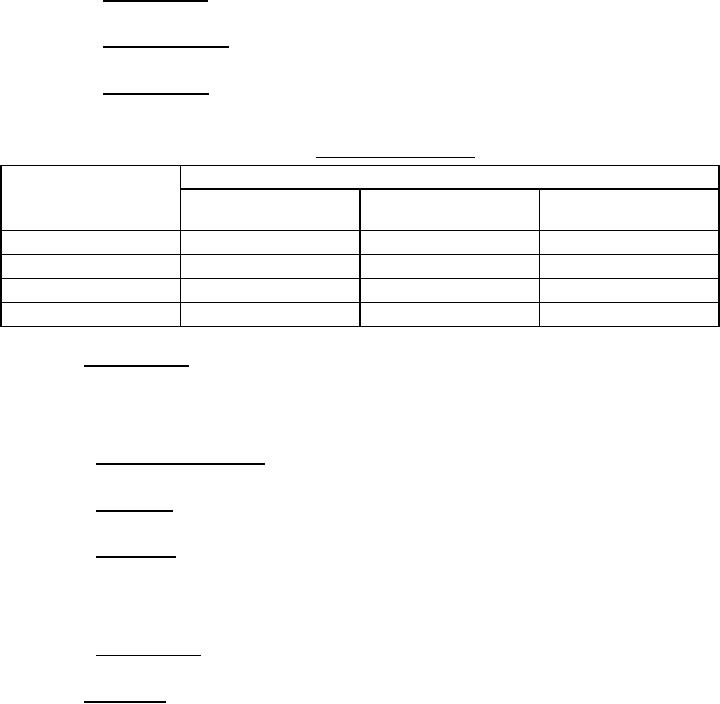

TABLE V. Mechanical balance levels.

Maximum allowable total amplitude (peak to peak)

Motor speed

Standard balance

Precision balance

Super-precision balance

(r/min)

(inch)

(inch)

(inch)

3000-4000

0.001

0.0005

0.0002

1500-2999

0.0015

0.00075

0.0003

1000-1499

0.002

0.001

0.0004

999 and below

0.003

0.0015

--------

3.5.2.2 Service C motors. Service C motors shall be marine type commercial motors. In addition to the

general requirements of 3.5.1 through 3.5.1.38, Service C motors shall meet the requirements of 3.5.2.2.1 through

3.5.2.2.4, 3.6, and the requirements of MIL-S-901 for Grade B shock. When specified (see 6.2), Service C motors

for operation in severe environmental service condition such as propulsion applications, exposure to occasional salt

spray, splashing, salt laden atmosphere, or submergence shall be provided with a sealed insulation system.

3.5.2.2.1 Protection against corrosion. Service C motors shall be protected against corrosion in accordance

with MIL-E-917.

3.5.2.2.2 Magnet wire. The magnet wire shall be round and of such size as to permit rewinding with round

integral sized copper wire in accordance with NEMA MW1000.

3.5.2.2.3 Ball bearings. Ball bearings shall be replaceable with the types specified in 3.5.2.1.5. Grease

lubricated ball bearings shall be selected so as to not exceed the ndm value of 350,000, where n is rotating speed in

r/min and dm is bearing mean diameter in millimeters. If this ndm value is exceeded, oil lubrication shall be

provided. The bearings shall be mounted such that the axial movement of the shaft shall be not more than 0.045

inch, including bearing end play (see 4.6.7).

3.5.2.2.4 Dynamic balance. Unless otherwise specified (see 6.2), the degree of balance shall be standard

balance as specified in table V.

3.5.2.3 Pump motors. When specified (see 6.2), pump motors shall meet Service A (see 3.5.2.1) or Service C

(see 3.5.2.2) requirements as applicable and shall be as follows:

a. For dripproof protected pump motors, when an air intake at the pump end of the motor is provided, the air

flow direction shall be at right angles to the shaft.

b. Except for motors with submersible or watertight enclosures, pump motors shall have a slinger with guard

on each motor shaft extension immediately outside the end shield to prevent entrance of water into the bearing

housing. The slinger shall have an external diameter of not less than 1.5 times the shaft diameter and an axial

clearance between the end shield and slinger not greater than 30 mils. The guard need not be furnished if the slinger

end shield or the pump configuration will ensure that no injury to personnel may result and no entrance of water into

the bearing housing can take place. Balancing rings may also serve the function of a slinger if so constructed.

c. The maximum value of full-load slip for 2-pole, centrifugal pump motors, 100 hp and above, shall not

exceed 1.25 percent at the conclusion of continuous full-load heat run.

23

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business