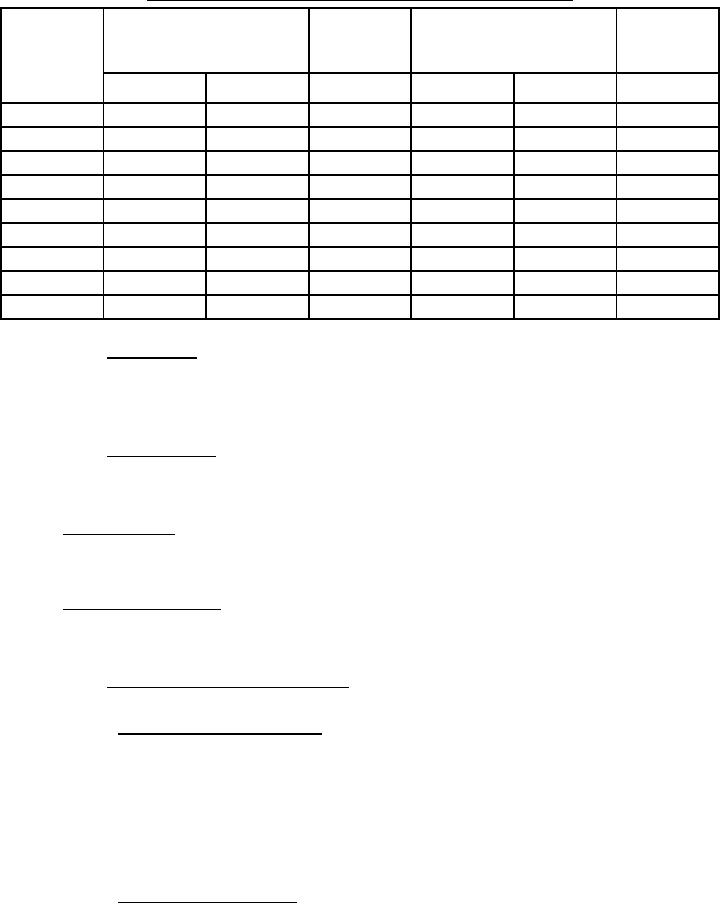

MIL-DTL-17060G(SH)

TABLE III. Bearing shaft, shaft shoulder, housing, and housing shoulder diameters - Continued.

Shaft

Housing

Shaft diameter

shoulder

Housing diameter

shoulder

Bearing size

diameter

diameter

Minimum

Maximum

Minimum

Minimum

Maximum

Maximum

316

3.1497

3.1502

3.550

6.6929

6.6939

6.250

317

3.3466

3.3472

3.840

7.0866

7.0876

6.620

318

3.5434

3.5440

4.060

7.4803

7.4815

7.000

319

3.7403

3.7409

4.290

7.8740

7.8752

7.380

320

3.9371

3.9377

4.488

8.4646

8.4658

7.940

321

4.1340

4.1346

4.685

8.8583

8.8595

8.307

322

4.3308

4.3314

4.875

9.4488

9.4500

8.898

324

4.7245

4.7251

5.276

10.2362

10.2374

9.685

326

5.1182

5.1189

5.827

11.0236

11.0248

10.315

3.5.2.1.5.1 Size and series. Unless otherwise specified (see 6.2), the bearings shall be of the size and series as

shown in table B of figures 1 through 4, as applicable. Bearings at opposite ends of the motor shall be a different

size. Grease lubricated ball bearings shall be selected so as to not exceed the ndm value of 350,000, where n is

rotating speed in r/min and dm is bearing mean diameter (see 6.6.2) in millimeters. If this ndm value is exceeded, oil

lubrication shall be provided.

3.5.2.1.5.2 Bearing mounting. Bearings shall be fully mounted in the end shields, not in a cartridge. Each

bearing shall be secured on the shaft by a locknut and a lockwasher or by a locknut utilizing a nylon lock. For

frames 215 and smaller, a beveled snap ring, Type III, Class 2 of MIL-R-21248, is acceptable in place of the

locknut. Mounting of bearings methods are as follows:

a. Fixed-free method. The fixed bearing shall be constrained axially in the housing by suitable housing and

end cap shoulders. For gear motors, the fixed bearing shall be on the gear end. The free end bearing housing shall

provide a clearance for thermally induced, axial shaft growth of not less than 0.020 inch for frames 182 through 326,

0.035 inch for frames 365 through 445 and 0.060 inch for frames 505 and larger.

b. Opposed shoulder method. The shaft end play shall compensate for any relative movement that may occur

between the shaft and the housing due to temperature differential between these parts. The end play shall be not less

than 0.020 inch for frames 182 through 326 and 0.030 inch for frames 365 and larger. The end play shall be not

greater than 0.045 inch for all frames (see 4.6.7).

3.5.2.1.5.3 Sealed bearings for surface ship motors. Surface ship motors meeting the criteria of 3.5.2.1.5.3.1

shall be provided with sealed bearings as described in 3.5.2.1.5.3.2.

3.5.2.1.5.3.1 Criteria for use of sealed bearings:

a.

Motor application is suitable for general purpose bearings per table II.

b.

Motor application shall not require a noise tested bearing per MIL-B-17931.

c.

Maximum bearing bore for 2-pole motors is 30 millimeters.

d.

Maximum bearing bore for 4-pole motors is 65 millimeters.

e.

Maximum bearing bore for 6-pole motors and slower is 90 millimeters.

f.

3.5.2.1.5.3.2 Sealed bearing characteristics.

a.

Double seal with rubbing seals, general purpose, in accordance with table II.

21

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business