MIL-DTL-17060G(SH)

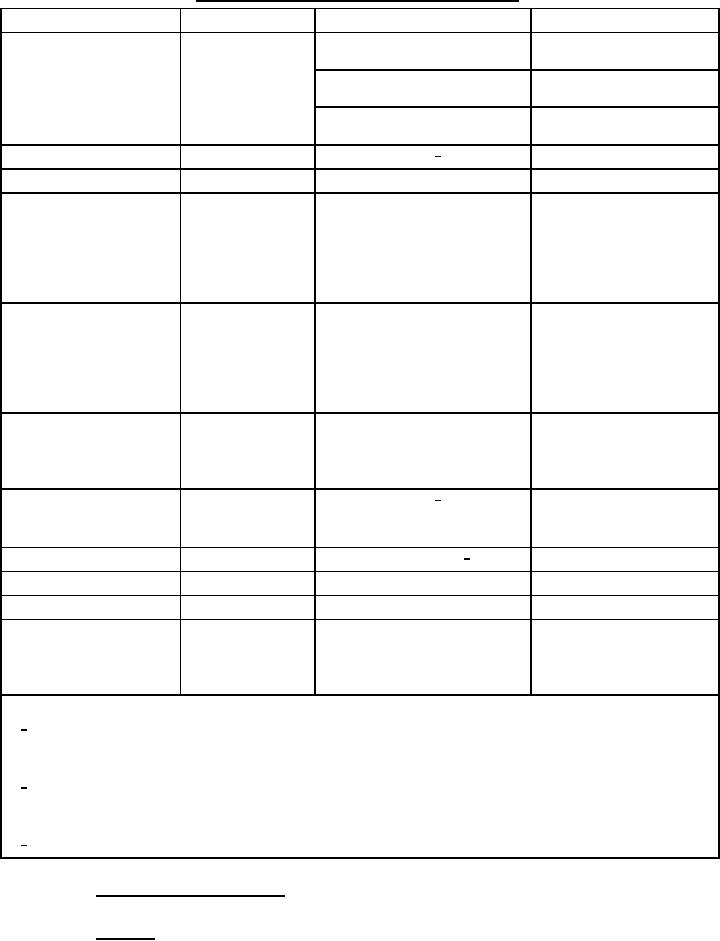

TABLE II. Minimum material requirements for service A motors - Continued.

Item

Limitation

Material

Specifications or remarks

Part covers for totally

Malleable iron

ASTM A47/A47M

--------

enclosed type machines

where the cover acts as a

Aluminum

ASTM B26/B26M

shield only, and not as a

support for another part

Plastic molded thermosetting

ASTM D5948

such as auxiliary or brake

Steel 1/

Quills and spiders

Where used

--------

Scraper

All sizes

Brass

Commercial

Close-coupled

Corrosion-resistant material

Shafts

Steel

pumps

All other motors

Tensile strength not less

than 75,000 lb/in2 and

elongation not less than

18% in 2 inches

Brass

ASTM B21/B21M

Shaft seals

All sizes

Bronze

ASTM B30, ASTM

B505/B505M

Corrosion resistant steel

ASTM A29/29M

Other inherently noncorrodible

material

Bronze

ASTM B30 or

Sleeve bearings

All sizes

ASTM B505/ B505M

Babbitt antifriction metal

ASTM B23,

Alloy Number 2

Steel 1/

ASTM A47/A47M

Terminal boxes

All sizes

Malleable iron

MIL-C-24707/5

terminal box covers

Nodular graphitic-3 iron

Copper, round 2/

Wire, magnetic

Types M2, K2, H2

NEMA MW1000

Varnish insulating

All classes

MIL-I-24092

Wire, end turn banding

All sizes

Steel and non-magnetic alloy

Commercial

Steel

Commercial

Wedges

All sizes

Brass

Commercial

Thermoset fiberglass

Commercial

Nodular graphitic-3 iron

MIL-C-24707/5

NOTES:

1/

Steel parts shall be cast, fabricated, wrought, or forged. Cast steel shall be in accordance with MIL-C-24707

and MIL-C-24707/1, Grades A1Q of ASTM A757/A757M or WCA of ASTM A216/A216M. For Grade WCA

of ASTM A216/A216M, the Charpy impact test conditions shall be 20 foot-pounds and minus 20 °F.

2/

Alternate wire sizes - sizes other than those in NEMA MW1000 may be used provided the motor design is such

as to permit rewinding with a size and shape wire specified in NEMA MW1000, having an equivalent or higher

temperature rating.

3/

Modular graphitic iron shall be furnished in either of the following two grades: 1) 60-45-15, 2) 60-40-18.

3.5.2.1.2 Solder for winding connections. Solder, where required for electrical connections, shall be silver-base

brazing alloy or copper-base brazing alloy in accordance with QQ-B-654 or AWS A5.8, respectively.

3.5.2.1.3 Windings.

18

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business