MIL-DTL-17060G(SH)

b.

Lubricated with grease in accordance with A-A-59685.

c. Grease fill, where D is the bearing bore in millimeters and N is the maximum synchronous speed in

revolutions per minute.

(1) For applications where DN ≥ 108000, grease fill shall be 33 percent (see 3.5.2.1.5.1).

(2) For applications where DN < 108000, grease fill shall be 45 percent (see 3.5.2.1.5.1).

Radial internal clearance shall be C3 per ABMA 20. When a looser clearance is required, it shall be C5.

d.

3.5.2.1.6 Sleeve bearings. The lubricating disc shall clear all obstructions. Oil shall be removed from the disc

by means of a brass scraper. The disc shall be attached to and rotate with the shaft, and shall deliver oil from the

sump to the upper portion of the bearing for lubrication.

3.5.2.1.6.1 Oil disc. The disc shall be of uniform cross-section with a channel on the inside diameter to contain

the oil while rotating. A brass scraper shall be mounted that shall remove oil from the channel of the disc for

bearing lubrication.

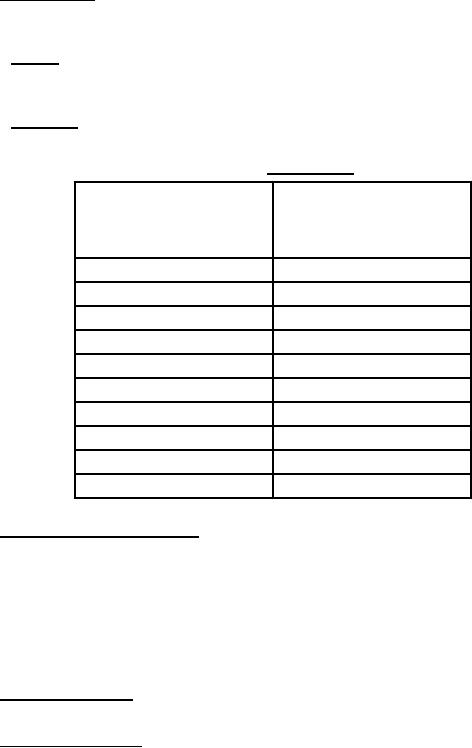

3.5.2.1.6.2 Clearances. Oil clearances shall be as specified in table IV.

TABLE IV. Oil clearances.

Maximum diametrical oil

Basic diameter of journal

clearance including shaft

(inches)

and bearing tolerances

(inch)

1.000

0.004

2.000

0.005

3.000

0.007

4.000

0.009

5.000

0.010

6.000

0.012

7.000

0.014

8.000

0.016

9.000

0.018

10.000

0.020

3.5.2.1.7 Method of attaching fans to shaft. Where fans are not an integral part of the shaft, one of the

following methods shall be used in attaching fans to the shaft:

a.

A key, shaft shoulder, and a nut with keyed lock washer.

b.

A key, shaft shoulders, and rings or tubing.

c.

A long key secured in a closed-end key seat with locked set screw secured on the key.

d.

A Woodruff key with a locked set screw secured on the key. The set screw shall not produce unbalance.

e.

A split fan with clamping bolts and key.

3.5.2.1.8 Thread cutting screws. Thread cutting (self-tapping) screws shall not be used to secure any part of the

motor.

3.5.2.1.9 Securing terminal leads. The method of securing terminal leads shall be such that stress from outside

the motor is not transmitted to electrical connections inside the motor. Unclamped, friction rubber bushings shall

not be used to secure terminal leads. Sealing compounds for anchoring leads shall not be used (see 3.5.1.25.3).

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business