MIL-DTL-17060G(SH)

3.5.1.23.2 Securing stator core to frame. Means shall be provided to prevent rotation of the core in the frame

and axial displacement of the core along the frame.

3.5.1.24 Terminal boxes and terminal box covers. Terminal boxes and covers shall be provided and securely

bolted or welded to the frame. Use of pipe nipples where they are necessary or where motors are to be used in

inaccessible locations shall be as approved (see 6.11). Terminal boxes shall be provided with conduit openings as

specified (see table I; for submarine applications see 3.5.2.5.4). For multispeed motors with multiple independent

windings, one conduit opening of the size indicated in table I shall be provided for each hp rating. For motors rated

over 250 hp, the conduit openings shall be sized to suit the number and diameter of ship cables specified (see 6.2).

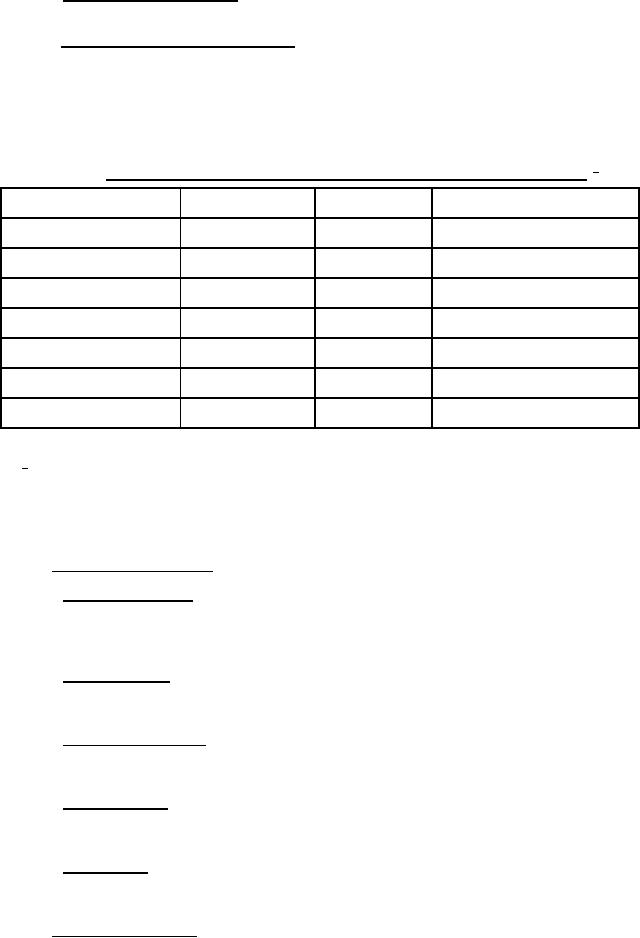

TABLE I. National pipe thread (NPT) assignments for motor terminal boxes nylon tubes. 1/

Maximum full-load amps

NPT

Tube size

hp

18

¾

2

1, 2, 3, 5, and 7½

25

1

3

10, 15, 10, 25, and 30

110

1½

5

40, 50, 60, and 75

185

2

6

100 and 125

250

2½

7

150

320

3

8

200

400

3½

9

--

NOTE:

1/

NPT sizes are based on the maximum expected three-conductor cable size. If cable size permits,

the hole size may be reduced to the next lower size by use of a reducing bushing which will be

inserted by the installing activity. If steel tubes are used, the installing activity shall provide the

proper size reducing bushing to fit.

3.5.1.25 Connections and terminals.

3.5.1.25.1 Securing connections. Connections (mechanical and electrical) shall be provided with locking

devices in accordance with MIL-E-917. Connections and leads shall be secured to prevent their coming in contact

with moving parts or being chafed by contact with stationary parts. Excess solder shall be removed from soldered

connections.

3.5.1.25.2 Field connections. In general and where practicable, field connections shall be made on the front

end (see 6.6.8). In split-frame motors, the field connections which will be broken for disassembly shall be readily

accessible.

3.5.1.25.3 Securing terminal leads. The leads shall be secured by a lead clamp or by anchoring them to the

motor windings so that no strain is put on the end connections. Where a lead clamp is provided, it shall be attached

to the frame and not to the end shields.

3.5.1.25.4 Cable connectors. The end of each motor lead shall be fitted with a connector for joining the motor

lead to the supply circuit cable or wire. Ship service cables and their terminal lugs shall not be supplied by the

motor manufacturer.

3.5.1.25.5 Flexible leads. Terminal leads shall be made of flexible, stranded insulated wire. Means to prevent

abrasion of the lead insulation by metallic edges of the motor frame, terminal box, piping, or cable clamp shall be

provided.

3.5.1.26 Lead wire identification. Lead wires shall be permanently marked in accordance with MIL-E-917.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business