MIL-DTL-17060G(SH)

4.2 First article inspection. Prior to the offering of any identical production unit for acceptance by the

Government, one motor shall have successfully undergone first article inspection as described herein. First article

inspection shall consist of the inspections specified in table XVIII. A complete first article inspection shall be

required after any change in design, material, or process which affects the performance characteristics of the motor.

4.2.1 Sealed insulation system suitability inspection. Suitability shall be determined through certification as

described in 4.6.19.1. Once a sealed insulation system has been qualified as specified in 4.6.19.1, recertification is

required in accordance with MIL-STD-2037.

4.3 Conformance inspection. Conformance inspection as specified in table XIX shall be performed on all

motors offered for delivery on a contract or order.

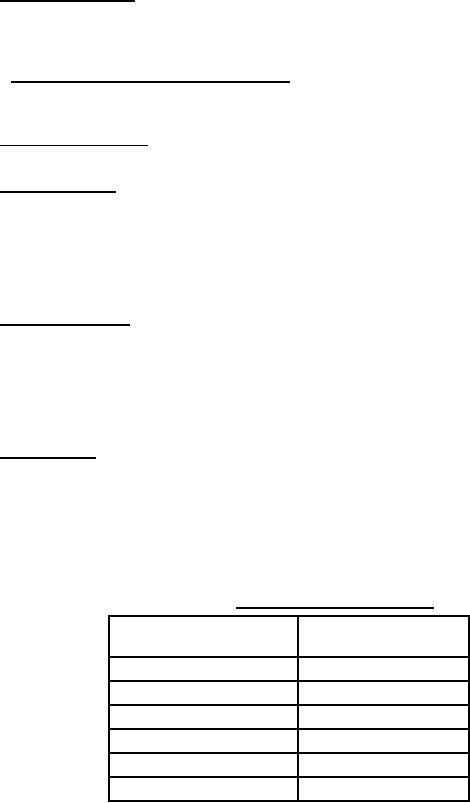

4.4 Periodic inspection. Samples for periodic inspection shall be randomly selected as specified in table XVII.

Periodic inspection shall consist of the inspections specified in table XVIII. Sampling for periodic inspection shall

be based on the number of motors of identical design and rating offered in the previous 12 months. Sampling shall

also be based on the number of motors of identical design and rating that were sampled in the previous 12 months.

If a motor has been submitted for first article inspection in the same 12 months as additional motors of an identical

design and rating offered for delivery, the motor shall be considered in figuring succeeding quantities for periodic

sampling.

4.5 Inspection conditions. Unless otherwise specified herein (see 4.6.14), all inspections shall be performed

under the test conditions specified below; ambient conditions shall be within these ranges but need not otherwise be

controlled:

a.

Temperature 77±59 °F (25±15 °C).

b.

Power input rated voltage and frequency (see 3.5.1.2).

Attitude normal operating position except as directed herein.

c.

4.6 Noncompliance. Any motor with one or more defect shall be rejected. In addition, if any motor fails to

pass an inspection, the manufacturer shall notify the cognizant inspection activity of such failure and take corrective

action on the materials or processes, or both, as warranted, and on all units of the product which can be corrected

and which were manufactured with essentially the same materials and processes, and which are considered subject

to the same failure. Acceptance and shipment of the product shall be discontinued until corrective action, acceptable

to the cognizant activity, has been taken. In the event of failure after reinspection, the manufacturer shall notify the

cognizant inspection activity of the failure.

TABLE XVII. Sampling for periodic inspection.

Number of motors

Sample size

(offered last 12 months)

1-12

1

13-25

2

26-50

3

51-90

4

91-150

5

151-280

6

39

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business