MIL-PRF-62368C(AT)

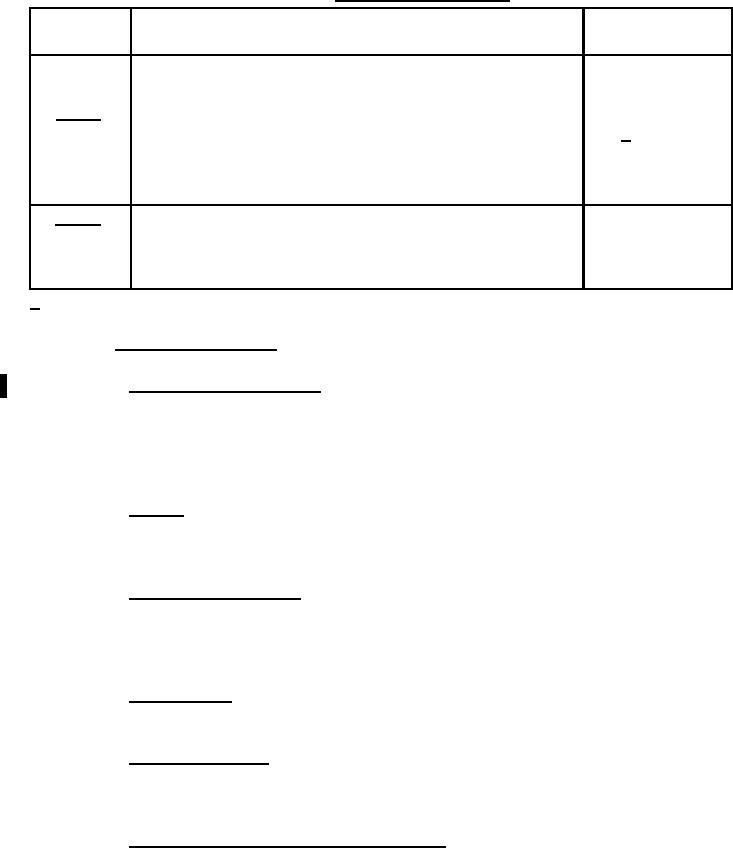

TABLE II. Classification of defects.

Method of

Category

Defect

examination

Critical

None

Major:

101

Dimensions affecting interchangeability, out of tolerance

SIE 1/

(see 3.3).

102

Improper identification marking (see 3.5).

Visual

103

Improper workmanship, affecting performance (see 3.6).

Visual

Minor:

201

Dimensions not affecting interchangeability, out of tolerance SIE

(see 3.3).

202

Improper workmanship affecting appearance (see 3.6).

Visual

1/ SIE = Standard Inspection Equipment.

4.5 Methods of inspection.

4.5.1 Materials and construction. Conformance to 3.2 through 3.3.4, shall be determined

by inspection of contractor records providing proof or certification that design, construction,

processing and materials conform to requirements. Applicable records shall include drawings,

specifications, design data, receiving inspection records, processing and quality control

standards, vendor catalogs and certifications, industry standards, test reports, and rating data.

4.5.2 Defects. Conformance to 3.3, 3.5 and 3.6, shall be determined by examination for

defects listed in table II. Examination shall be visual, tactile, or by measurement with standard

inspection equipment.

4.5.3 Rotation of output shaft. To determine conformance to 3.4.1, the motor shaft shall

rotate in a counterclockwise direction when viewed from the shaft end with positive voltage

applied to the + (positive) terminal of the filter and negative voltage applied to the - (negative)

terminal of the filter. Reverse lead polarity stated above and verify clockwise shaft rotation.

4.5.4 No load speed. To determine conformance to 3.4.2, the motor output shaft speed

measured with no load applied shall be no more than 36 rpm in both directions of rotation.

4.5.5 Zero torque current. To determine conformance to 3.4.3, the current drawn by the

motor under the condition of no load applied to the output shaft, shall be measured and shall not

exceed 0.5 A dc.

4.5.6 Speed and current at 640 oz-in. (4.52 N-m)). To determine conformance to 3.4.4,

the motor output shaft shall be connected to a loading device such as a dynamometer and a

speed-indicating device such as a tachometer. The loading shall then be adjusted to not less than

640 oz-in., and the resultant speed and current shall be measured for each direction of rotation.

The speed shall be no less than 22 rpm, and the current shall be no more than 1.5 A dc.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business